EXPLORATION OF VARIABLES IN SHAPE TRANSFORMATION

by Dido Tsigaridi & Mikael Powell December 15, 2005

[excerpted from slide and video presentation]

Part I - Introduction to Material

A. Type 2 – Energy Changing Material

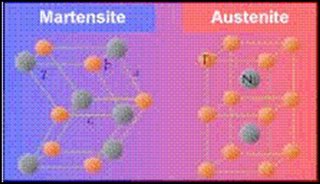

Direct Linear Change is caused by a temperature difference. This material has a uniform crystal structure that radically changes to a different structure at a distinct temperature.

B. Material States and Training - Shape Memory wires stressed at high temperatures react when subjected to heat.

Several elements in the Periodical Table of Element have been found to have shape memory effect qualities.

1. Originally SMA was discovered with Gold-Cadmium alloy but this was too expensive and toxic.

2. Copper-zinc alloy is used for extreme cold conditions.

3. Nickel-titanium is safer, less expensive, has high compatibility with living tissue and better deformation recovery ratio.

4. Properties: NiTi is temperature-activated. When cooled it becomes pliable, to be formed as you wish. Upon returning to its warm, resilient state, it "remembers" its programmed shape and returns to it - applying force against anything it its way. Nickel titanium is very resilient. It is lightweight, non-corrosive, biocompatible, wear resistant and more. Engineers specify nickel titanium for two qualities: shape memory and super-elasticity. Super-elasticity describes the material's ability to recover from large amounts of strain. A NiTi component can fully recover from strain values up to 8%. (Stainless steel, by comparison, will withstand only 2% strain.) The super-elasticity of NiTi allows it to perform functions that would permanently deform other alloys. If you design a NiTi spring, for instance, to have a transition temperature of 100 degrees, it behaves like a regular spring at temperatures above 100 degrees. (Here it's said to be in an austenitic phase.) Below 100 degrees, it's weak and pliable like a piece of solder. (This is its martensitic phase). Heating the spring above its temperature transition range causes the material to recover its former spring shape with considerable force.

The temperature at which this phase transformation occurs can be adjusted over a wide range.

C. Variables

1. Time – (effects include speed and fatigue)

[pix w/ graph]

2. Heat- (effects include trajectory)

Part II –Experimentation of Phenomenon Variables

A. Research on the effect of XXXX (above)

1. Introduction- Electric Pistons are an all-electric linear actuator shape memory wire mechanism that shortens in length with great strength and speed. Manufactured by Mondo-tronics Inc. it is calibrated to work with a 6 volt power pack with a maximum amperage of 5.0 and minimum amperage 2.0. Experimentation is to review how XXXX effect XXXX.

2. Procedure – One end of the piston is fixed to the wall. It is deformed to a specific length. Application is inducesd. Time is calculated.

3. Conclusion - Electric Pistons

Mode1 Mode2 Mode3 Mode4 Mode5 Mode6 Mode7

x:xxsec x:xx sec x:xxsec x:xxsec x:xxsec x:xxsec x:xxsec

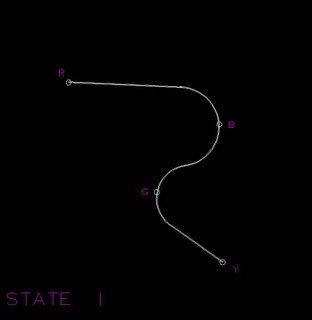

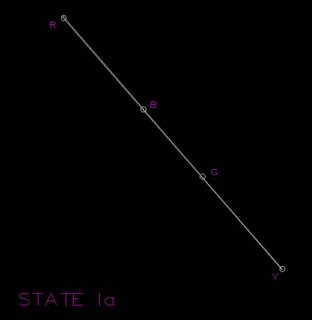

B. Research on the effects of X2 –Material Mode Photograph (above)

1. Introduction - Material is manipulated to explore transformation.

2. Application – XXXX–Charted Mode I, II, IIabc (above)

3. Conclusion - Variables can be systematically interacted exhibiting proportional responses.

C. Research on Re-Set Capabilities

1. Introduction: Many SMA components need to be reset to state I by mechanical means. We are researching whether a reset phenomenon can be developed to allow for a self-perpetuating cycle.

2. Procedure: Two Electric Pistons (an all-electric linear actuator shape memory wire mechanism) were used. The devices were connected together and systematically activated.

3. Conclusion: Reactions can be effectively induced to provide reset capability.

(COPYRIGHT © 2006 TSIGARIDI/POWELL. All Rights Reserved)

-END-